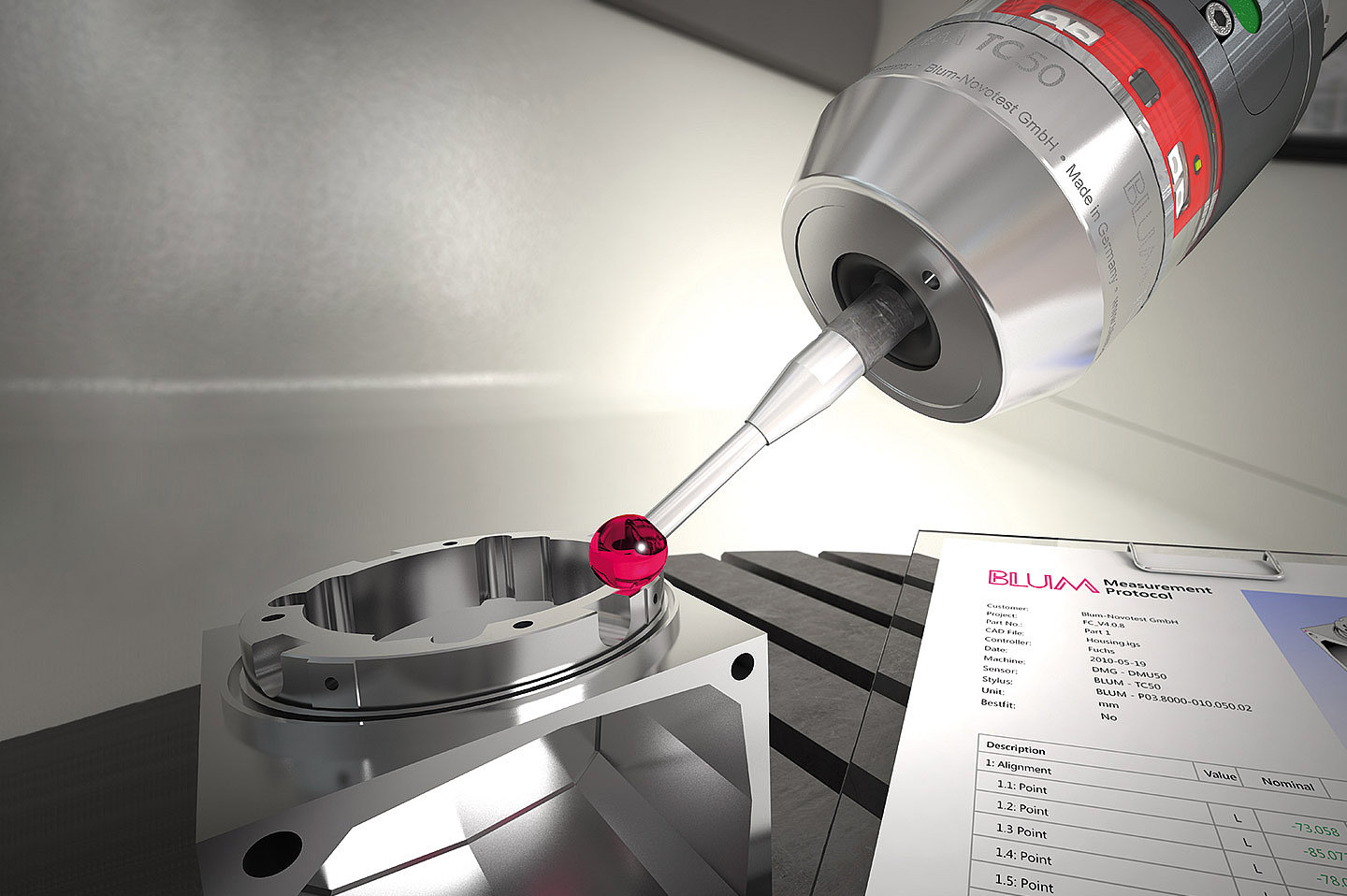

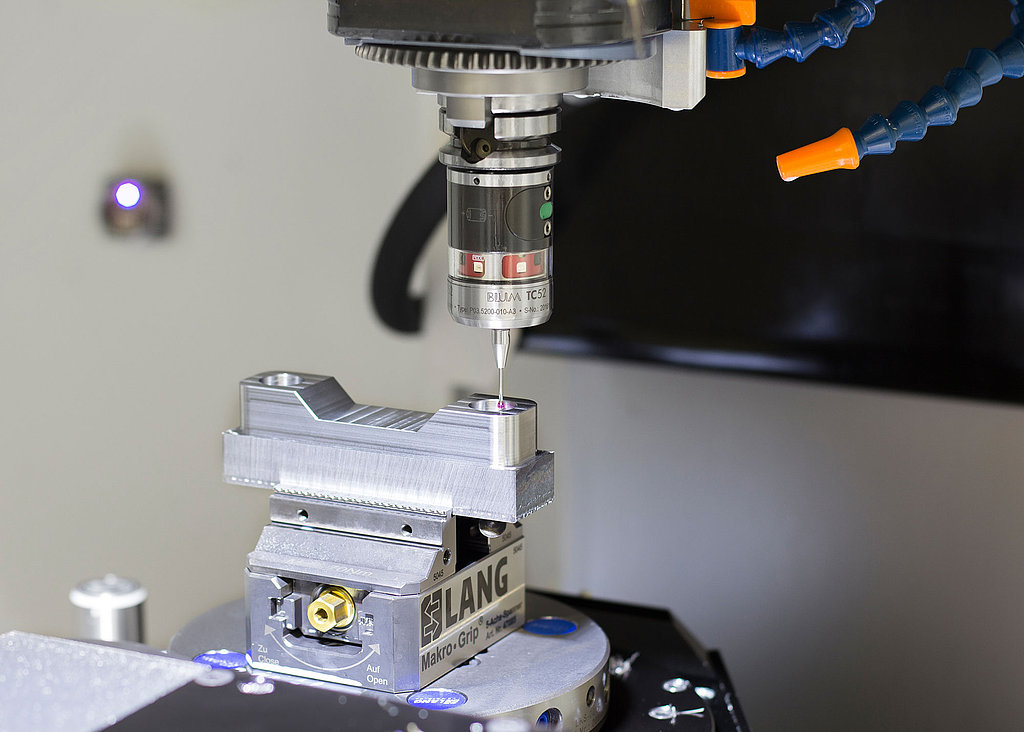

BLUM touch probes are used for fast and automatic workpiece measurement and workpiece referencing in machine tools. Specially designed for the harsh conditions in these machines, the probe systems are an effective solution for improving the accuracy of your workpieces and the productivity of your manufacturing lines.

- Extremely high travel and probing speeds

- Maximum measuring precision in all probing directions

- Reliable measurements also under coolants

- Practical design – e.g. self-centring stylus

- Very long battery life

- Mechanically robust design

- Enable low-manned operation

- Realise continuous process chains

- Workpiece touch probe of exceptional quality and precision

A touch probe uses tactile measurement to record the dimensions (length, width, height), form elements (straightness, flatness, roundness, cylindricity) and position elements (parallelism, squareness, angle of inclination, symmetry) of workpieces in the machining industry. The contact measurement is carried out by touching the workpiece with a ruby ball using a predefined force. Inside the touch probe, a wear-free, optoelectronic signal is generated when the stylus is deflected: a precision pin moves into a light barrier, generating the switching signal for recording the measured value.

BLUM has two models of touch probes: multidirectional and bidirectional touch probes.

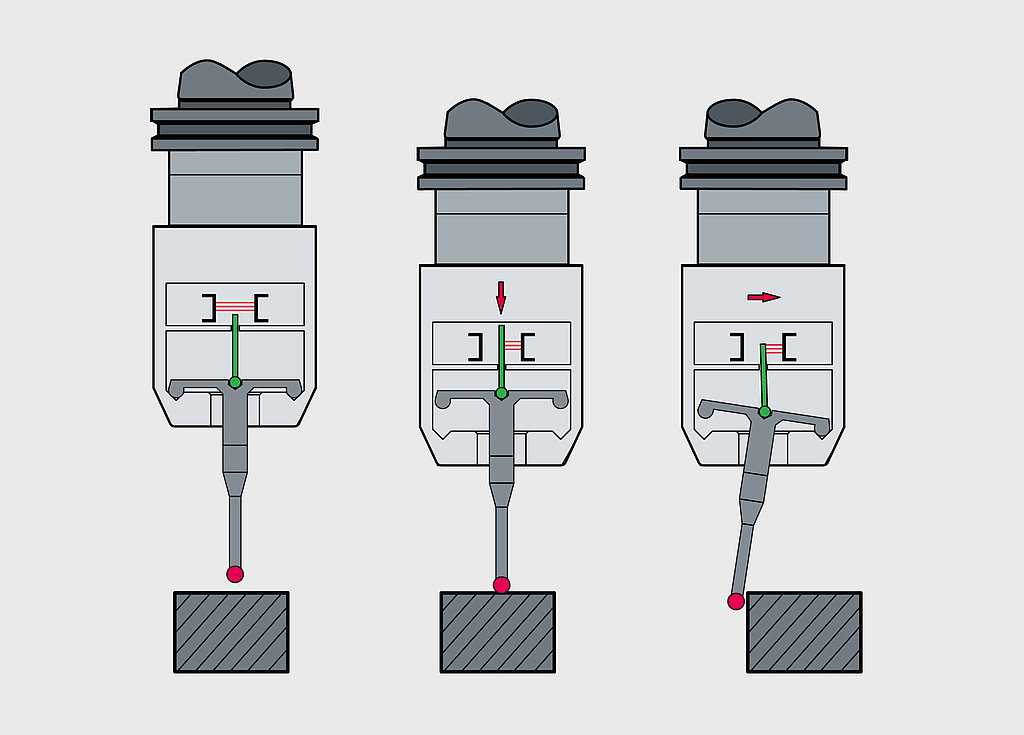

Compared to many other touch probes, a touch probe with a multidirectional optoelectronic measuring mechanism does not show different measuring results when probing in different directions. When the measuring insert touches the workpiece, a miniature light barrier is shaded inside. This non-contact switching principle is wear-free and allows a significantly higher measuring speed than comparable probes. BLUM consistently pursues the strategy of uniform, direction-independent probing characteristics with its touch probes.

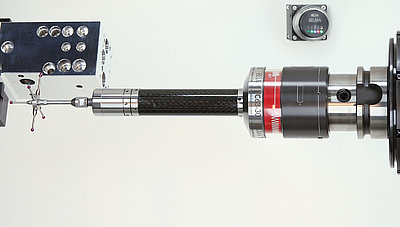

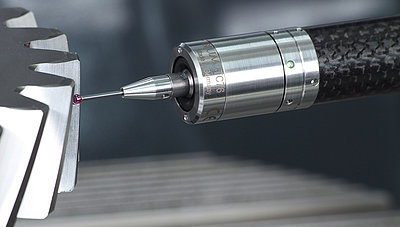

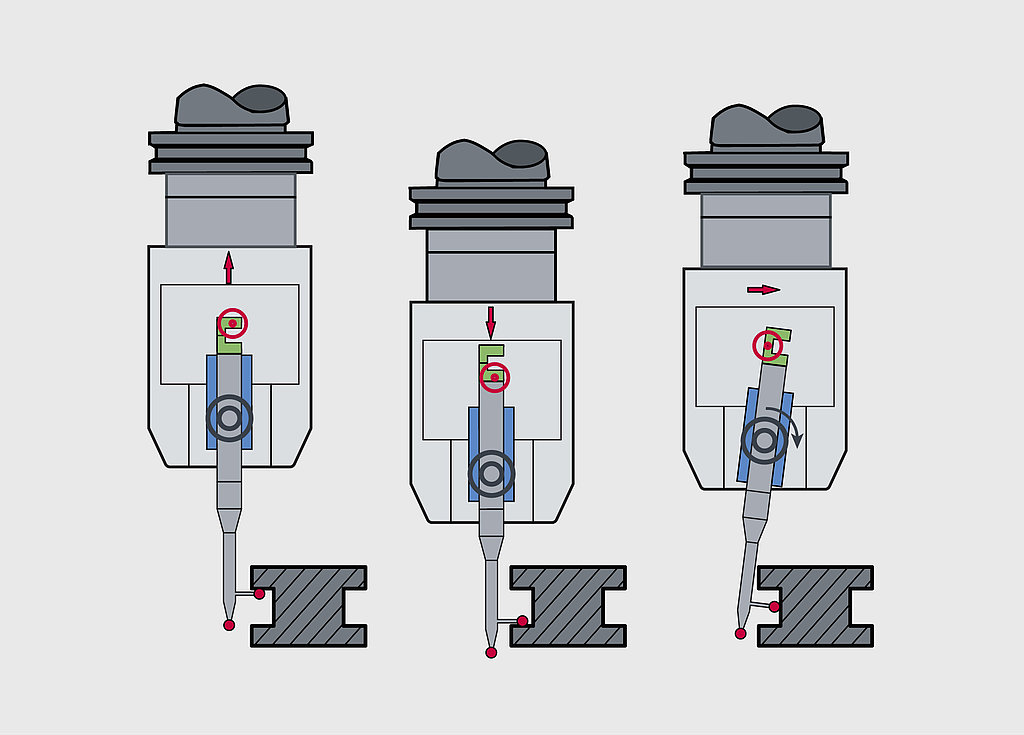

A touch probe with bidirectional measuring mechanism is characterised by the deflection either in the Z direction or in a structurally defined X/Y direction by orienting the spindle accordingly. By avoiding a premature switching signal when touching the coolant film on the workpiece, the bidirectional measuring mechanism, in contrast to other probes, allows measuring speeds of up to 5 m/min, accelerations of up to 5 g and repeatability of less than 1 µm.

BLUM touch probes are mainly used for in-process measurement of workpieces in the production of finely machined precision parts. The fast and reliable touch probes, which carry out precise measurements on the workpiece in the original clamping directly in the machine room, open up completely new possibilities for general mechanical engineering, tool and mould making, series production, workpiece and tool measurement in turning, grinding and milling centres and special measuring tasks. In-process measurement means that the workpiece does not have to be unclamped for measurement with the touch probe and can be reworked if necessary.